Non-Seamless Metallic Cladding contributing to Corrosion Under Insulation (CUI) is a serious problem worldwide on Hot Thermal and Cryogenic insulation applications. It is calculated that $2,000,000,000 USD per year is lost in pipeline replacement, repairs, and production down times due to CUI.

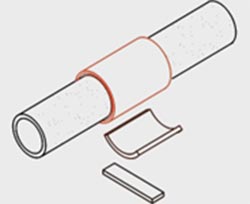

Typically, destruction and corrosion of insulated pipelines using metallic cladding in hostile environments which results in CUI and significant extra cost to the installation due to water ingress into the insulation system as metallic cladding is non seamless and is prone to mechanical damage

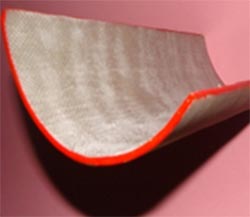

Not only is the health and safety and environmental impact of the products important, but the application must also be able to withstand the harsh rigors of the Marine environment, the temperature variations, and the UV extremes Trinity has developed UV curing Non-Metallic Cladding and Twin curing composites. This has provided unique engineering opportunities for application solutions in the Oil & Gas, Water, Chemical and Marine industries. The photo below illustrates a hybrid Polymer resin, which was post applied after installation of the OIP laminate. This was important in a particularly harsh marine location subject to seasonal high velocity wind-blown C5 environment which could cause moisture or water ingress into metallic cladding.

|

|

|

|

|---|

|

|

|

|

|---|